We are highly committed to quality and freshness of our raw materials which comes from the unpolluted waters around us. Due to this our products are the best environmental choice around the globe. Our fishermen are well trained and fishing boats are well equipped with the most modern facilities.

The fish is transported in refrigerated trucks as per the company requirements and at receiving, goods are checked same as company goods and only acceptable goods are received.

For each lot boat details are received from the suppliers. Time to time company representatives do inspections on boats – (company own suppliers and contractors) to check its hygienic conditions and operations.

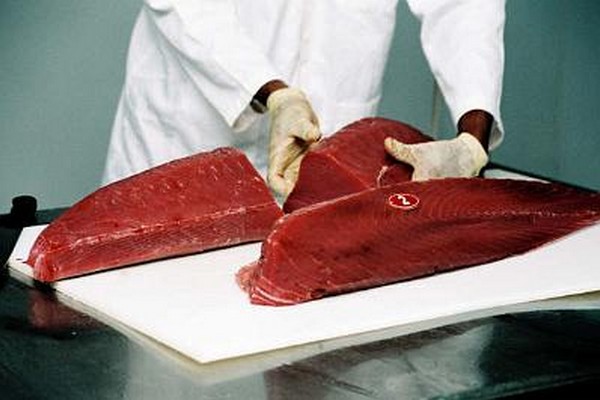

Our processing plants work strictly according to HACCP rules. A certified quality controller critically tests each fish for Histamine and other health issues. Our Products are packed in to European standard approved by the EU.

These are the checks conducted by the factory when receiving the fish lot

– Organoleptic checks

– Laboratory testing

– Temperature checking